Digital printing technologies are by nature more sustainable than conventional alternatives and offer a way forward towards clean, efficient and profitable manufacturing. As an industry, all sectors of the textile community are embracing sustainable manufacturing practice from the fibers that we choose to spin the fabric preparation chemistry that we use to coat and finish through the printing machinery and inks formulations which we print. Massive investment has and continues to be made within every sector many of which now collaborate to further develop innovative new stream-line processes and technologies.

Sustainability can only exist alongside supply chain transparency and collaboration is the key to success.

Textile manufacturing across multiple industries using conventional technology previously consumed massive resources and generated (now valuable) waste as a by product.

Prior to digital disruption the textile industry consumed massive amounts of water and energy by contaminating the environment with dyestuff and numerous toxic chemicals used in the manufacture of textile fabrics, inks, printing and finishing of products.

Digital textile printing saved over 40 billion litres of water worldwide in 2018. Offering an efficient solution when compared to traditional water usage for rotary screen printing which is in the region of 50-60 litres of water per metre. Digital textile printing also uses smaller quantities of colour typically 10% of the volume used when compared to screen printing. Using pigment inks as an example and its requirement for fixation only finishing (no washing) uses less than 10 litres of water per metre.

Digitally printed cotton eliminates the consumption of water and the discharge of noxious effluents. Using low volumes of liquid dispersions of pigment colours, therefore offering a positive environmental impact. Digital textile printing using pigments also removes the need for water and energy greedy post processing since colour fastness is achieved by heat fixation alone as opposed to lengthy steam fixation and washing off procedures.

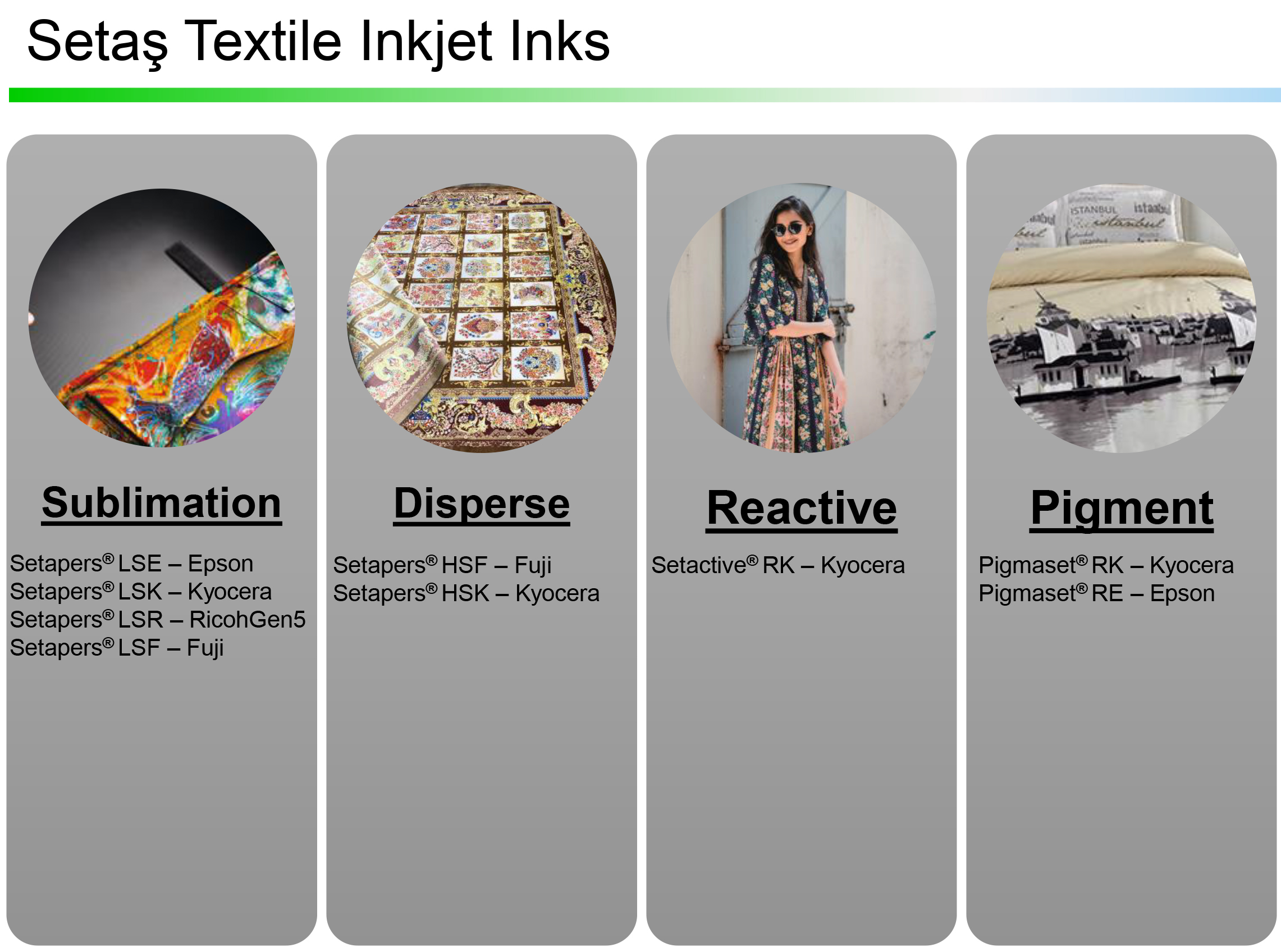

Setaş has established Setaş Digital in 2017 as an outcome of 4 years of intensive R & D activities. The main purpose of Setaş Digital is to reduce imported digital ink substitution in our country and to produce high quality inkjet meeting the requirements of textile sector. Our water based digital printing inks produced with nanotechnology which are suitable for different applications for various types of fabrics as below:

Setapers® LS Inks: Digital printing ink range developed with nano technology for printing on polyester fiber. Setapers® LS inks applied by transfer printing method ensuring high color yield and vivid and brilliant colors

Setapers® HS Inks: Disperse digital printing inks produced for fast printing and in accordance with direct disperse printing with high light and washing fastness is obtained with a high color yield

Setactive® RK Inks: Water based reactive digital printing inks developed with nano technology for printing on cellulose fibers. Reactive ink range produced from synthesis are environmentally friendly and innovative dyes designed to produce brilliant and deep colors

Pigmaset® P Inks Pigmaset® inks range is designed as water based, low viscosity in order to work on piezo-head machines by Setaş. Provides application advantage due to easy printing process as well as cost and time saving, also they are environmentally friendly inks. Pigmaset® inks can be applied to all kinds of fabrics which provides pro-longed life to the products used outdoors, due to UV rays durability features